KANWAY’s KW-NT technology will extensively and steadily support your industrial competitiveness.

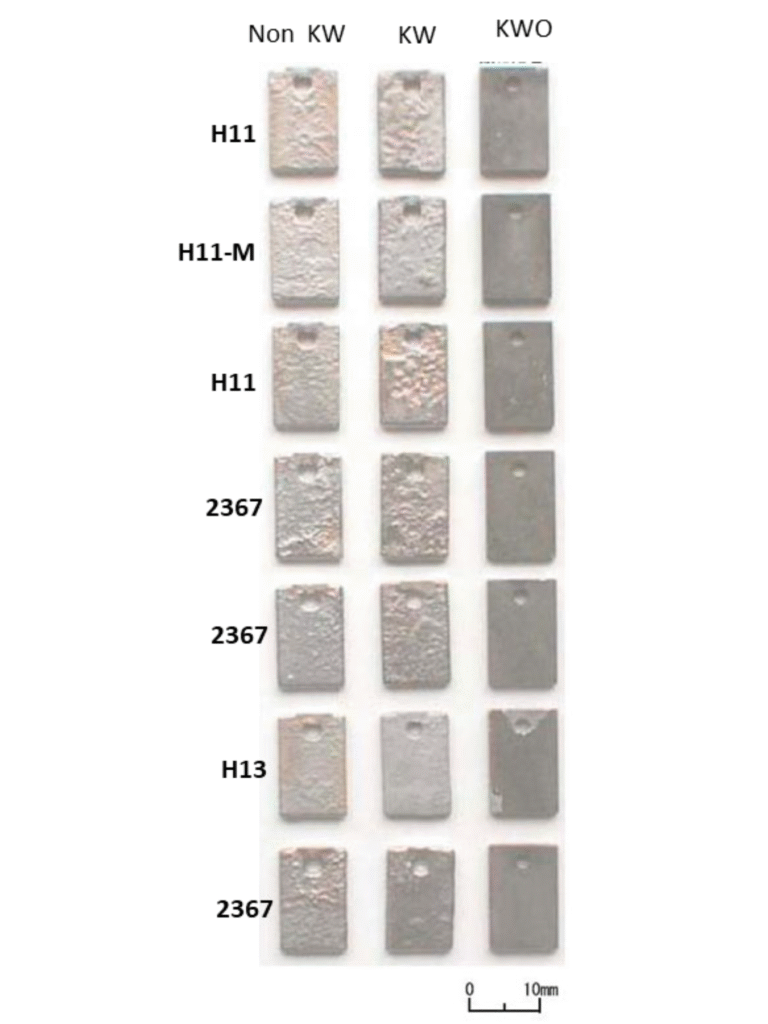

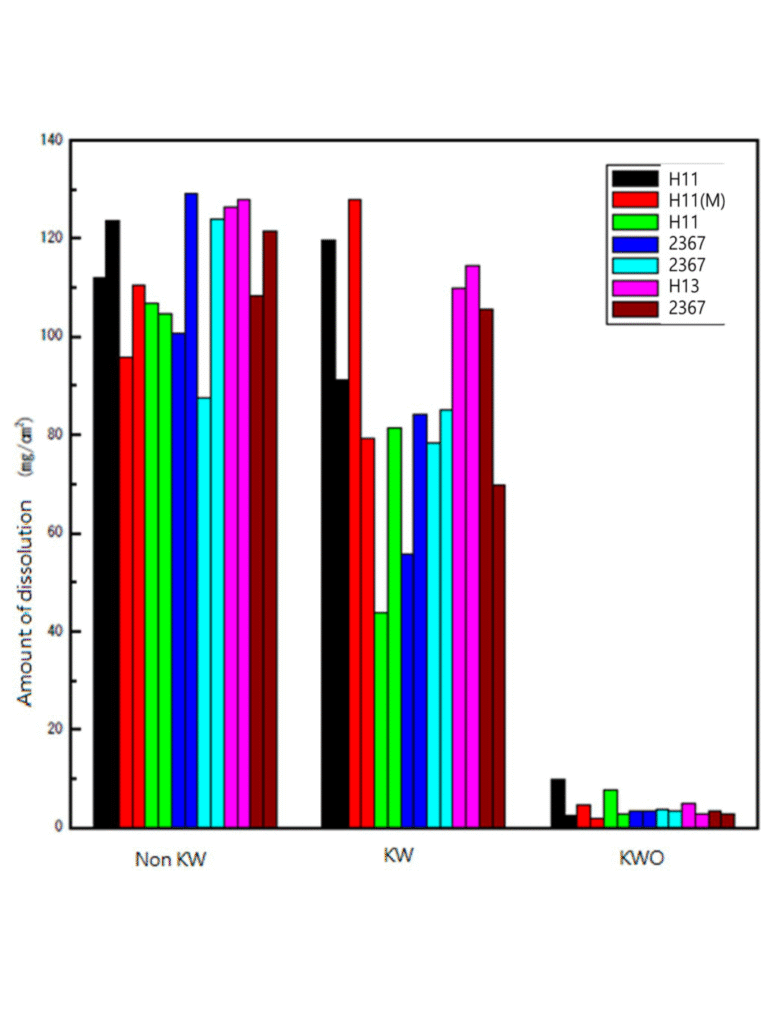

KW-NT has the advantage of minimizing damage to high-pressure die casting molds and hot forging molds

KW • KWO

The compressive stress layer formed by the nitriding diffusion layer effectively suppresses the occurrence and growth of thermal fatigue cracks.

No formation of a brittle white nitriding layer (Fe₂₋₃N, Fe₄N) on the surface, thereby preventing the formation of an embrittlement layer.

The formation of Fe-Cr₂O₄ or Cr₂Non the surface prevents grain boundary oxidation and damage by molten aluminum at high temperatures.

Fe-Cr₂O₄ or Cr₂Nformed within initial thermal cracks can slow down the crack growth rate.

The surface layer maintains hardness for a longer period, mitigating thermal softening caused by high temperatures.

The nitridedsurface layer reduces intermetallic friction.

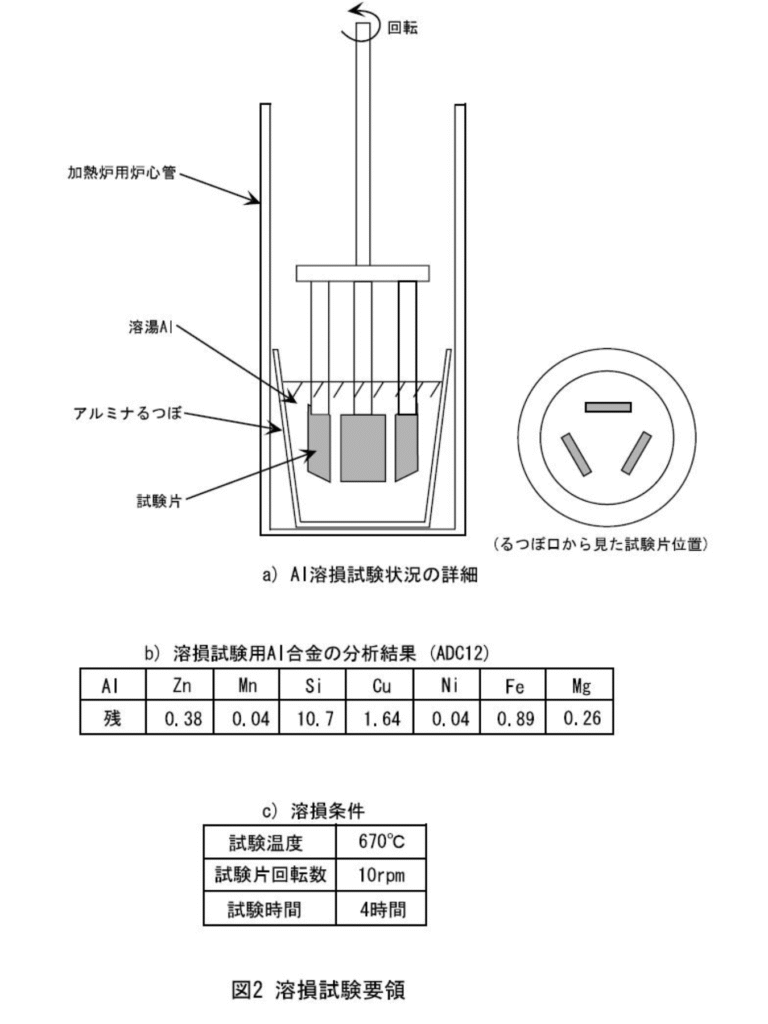

Process Specifications

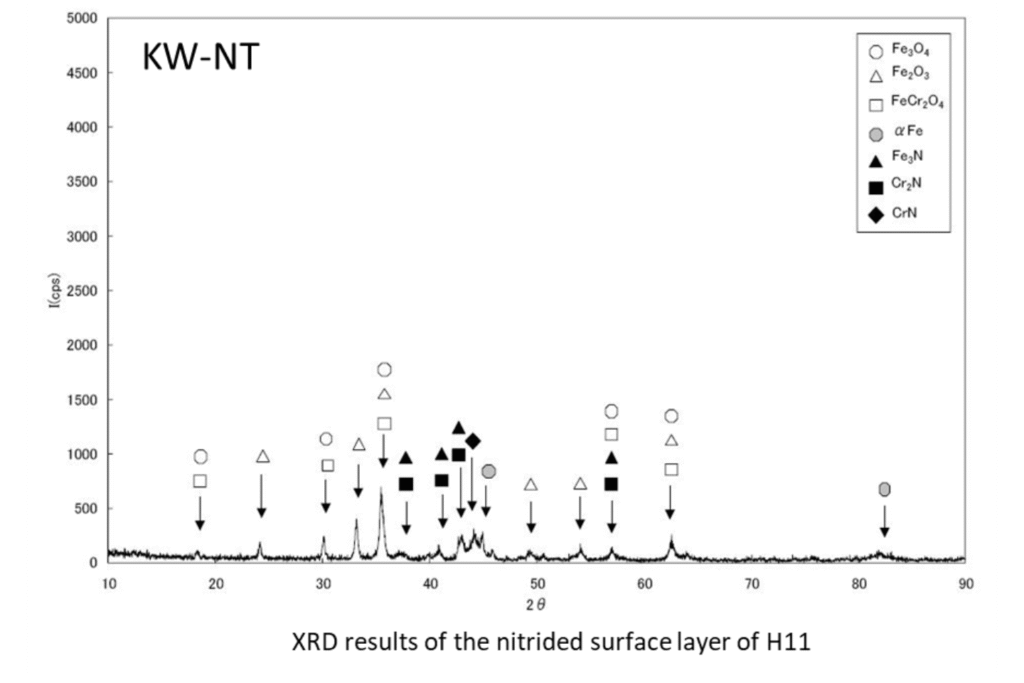

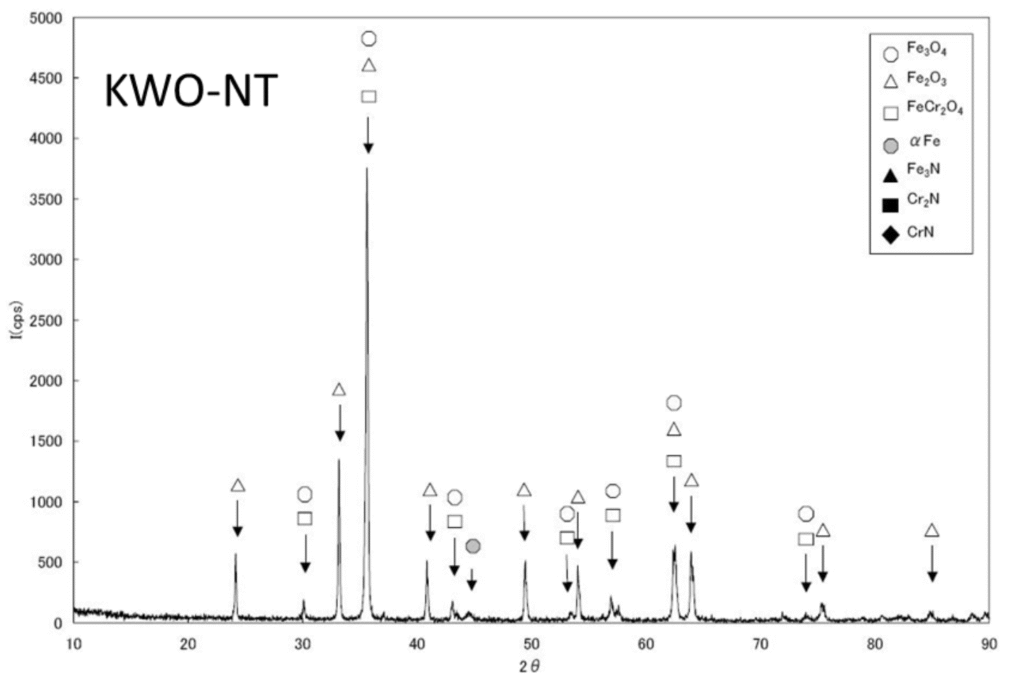

KW & KWO (Nitriding Treatment) Surface XRD Results

Advantages and Application Explanation of the Special NitridedLayer of KW-NT

Microstructure and Application Explanation

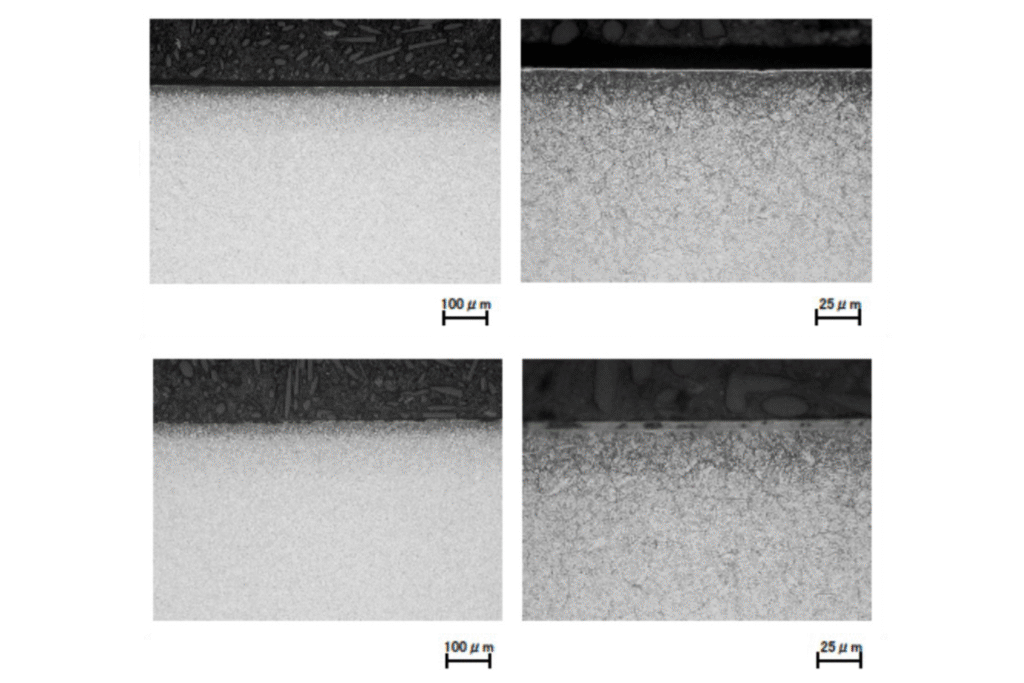

The metal structure treated with KW exhibits a gradual decrease in nitrogen (N) concentration (hardness) from the surface toward the interior, closely bonding with the base material while maintaining its original toughness. Depending on operational conditions, the structure can be adjusted to form with or without a compound (white) layer.

Due to its structure, the nitrogen diffusion layer formed by KW treatment generates compressive stress within the diffusion layer, delaying the formation of tensile stress that leads to metal failure and thereby extending the service life of metal molds and components. As the surface hardness decreases gradually, even extremely thin parts of 0.1 mm can retain the toughness of the base material.

The formation of moderate surface compressive stress can truly and significantly delay the occurrence and growth of thermal fatigue cracks in high-pressure die casting molds and hot forging molds.

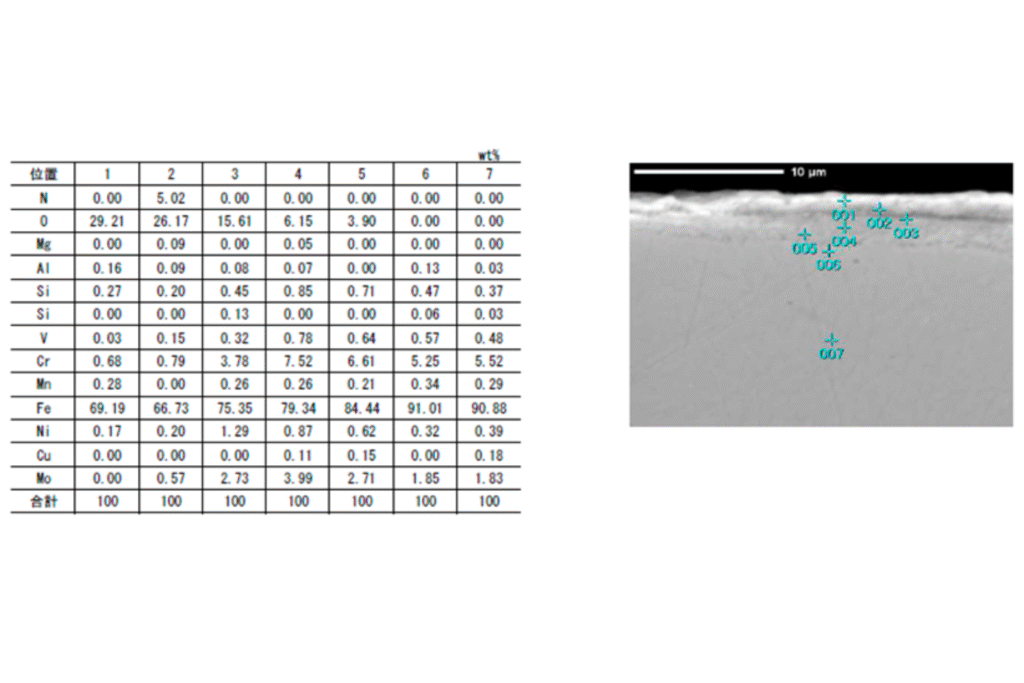

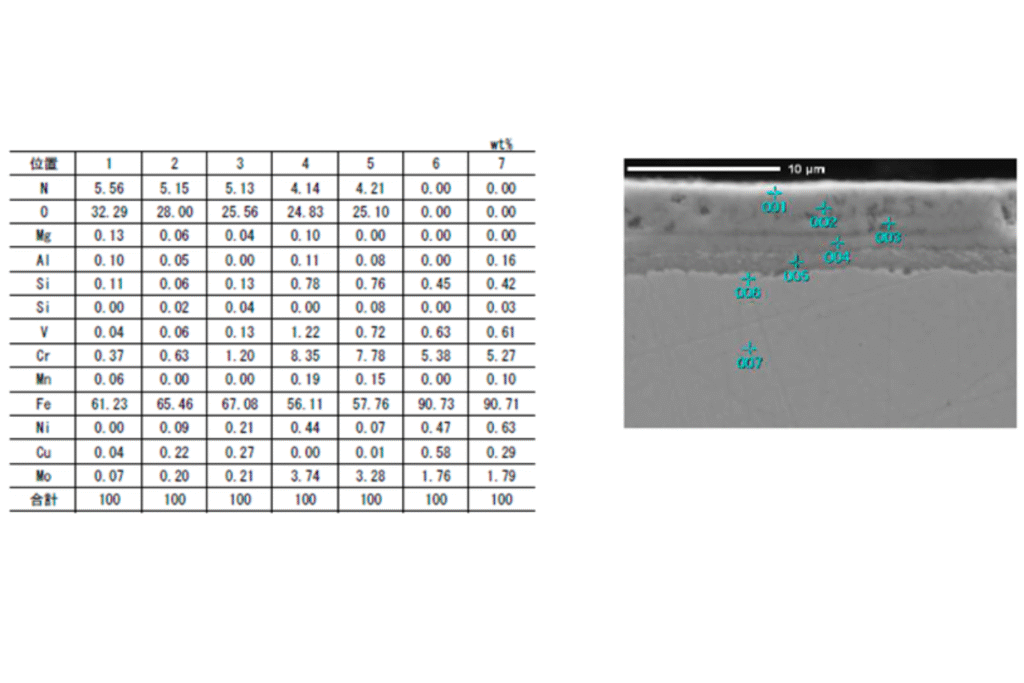

KW & KWO EDS Analysis results of Surface organization

KW (Nitriding Treatment) EDS Analysis results of Surface organization

NitridingTreatment conditions :350℃x 1Hr、520℃x8Hr

Oxidation Treatment conditions :None

KWO (Nitriding –Oxidation Treatment) EDS Analysisresults of Surface organization

NitridingTreatrmentconditions :350℃x 1Hr、520℃x10Hr

Oxidation Treatment conditions :350℃x 1Hr、520℃x6Hr (In the atmosphere)

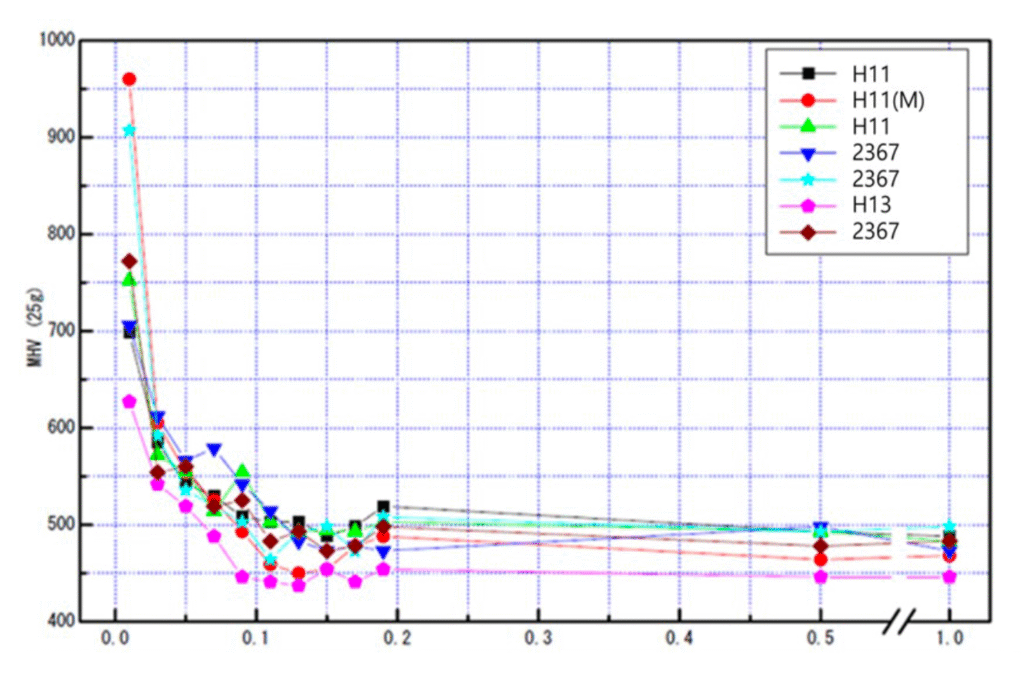

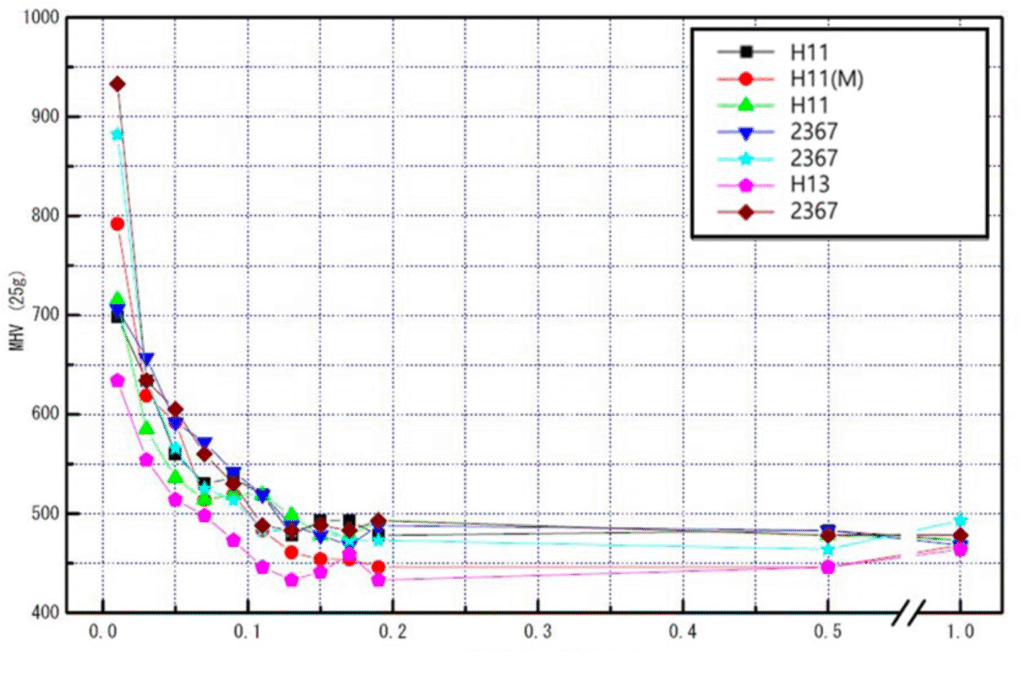

Hardness Distribution of KW & KWO Nitrided Diffusion Layer

KW (Nitriding Treatment) Hardness distribution

Distance from the surface (mm)

KW0 (Nitriding Treatment) Hardness distribution

Distance from the surface (mm)

Treatment Temperature:

The KW process allows for adjustable treatment temperatures within the range of 450°C to 590°C. The optimal treatment temperature is tailored to the specific steel grade and the precision requirements of the workpiece.

Effective Depth of Nitrided Diffusion Layer:

The depth of the nitrideddiffusion layer can be adjusted based on usage requirements. A depth within 10 μmis recommended for ultra-precision components, while 50–70 μmis ideal for components requiring both strength and toughness. For high-pressure die casting molds and hot forging molds, 70–100 μmis suggested. Depending on the steel type, the maximum achievable depth can reach 120–150 μm.

Uniformity of Surface Diffusion Layer:

Coatings (PVD) or conventional nitriding often result in uneven coating or diffusion layer thickness due to complex geometries. Thanks to its unique diffusion mechanism, Kanwaytreatment ensures that any complex-shaped object—including those with blind holes or grooves—can achieve a nitridedlayer of uniform thickness.

KW Treatment for Stainless Steel SUS Series:

Conventional nitriding requires strong acid pickling to remove the surface chromium oxide film before treating stainless steel. In contrast, KW treatment can directly nitride SUS304, 316, 310, 420, 440C, and other stainless steels, achieving surface hardness levels as high as Hv1000–1300 while eliminating the need for prior strong acid cleaning.

KW-NT : Solid-State Powder Nitrid

The powder from KW treatment is a non-toxic inorganic substance.

• Can be treated as general waste.

Corrosion Resistance Test of KW-NT Series